After sludge is treated and disposed by a series of methods, there are generally the following final disposal methods for the dried sludge:

Energy utilization

For sludge, engineering technology can be adopted to extract and synthesize the organic matter and heavy metal elements rich in sludge, so as to realize energy recovery. At present, sludge can be treated in an anaerobic environment, so that the microorganisms contained in the sludge can be fully fermented and degraded, and finally produce methane gas. After the methane is collected, it can be used as clean fuel, and the residual solid can be used as organic fertilizer. In the protection of the environment at the same time, the realization of high resource requirements. In addition, there are a series of technologies such as low-temperature sludge oil production technology and sludge fuel utilization technology to realize energy utilization.

Sludge for building materials

Another way to solve the sludge disposal is using sludge production of building materials, asphalt, through engineering technology can achieve the sludge system sludge ceramics grain biochemical fiberboard, sludge, sludge system of ecological cement and other building materials, the sludge of waste disposal requirements, protection of the environment at the same time to achieve the sludge.

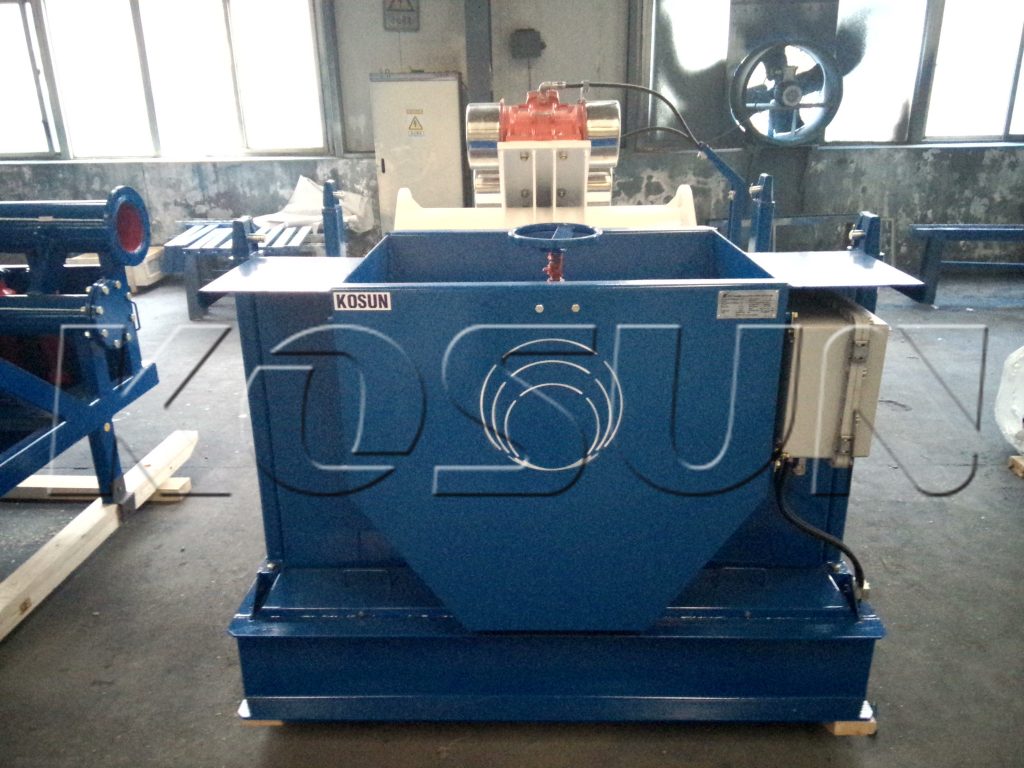

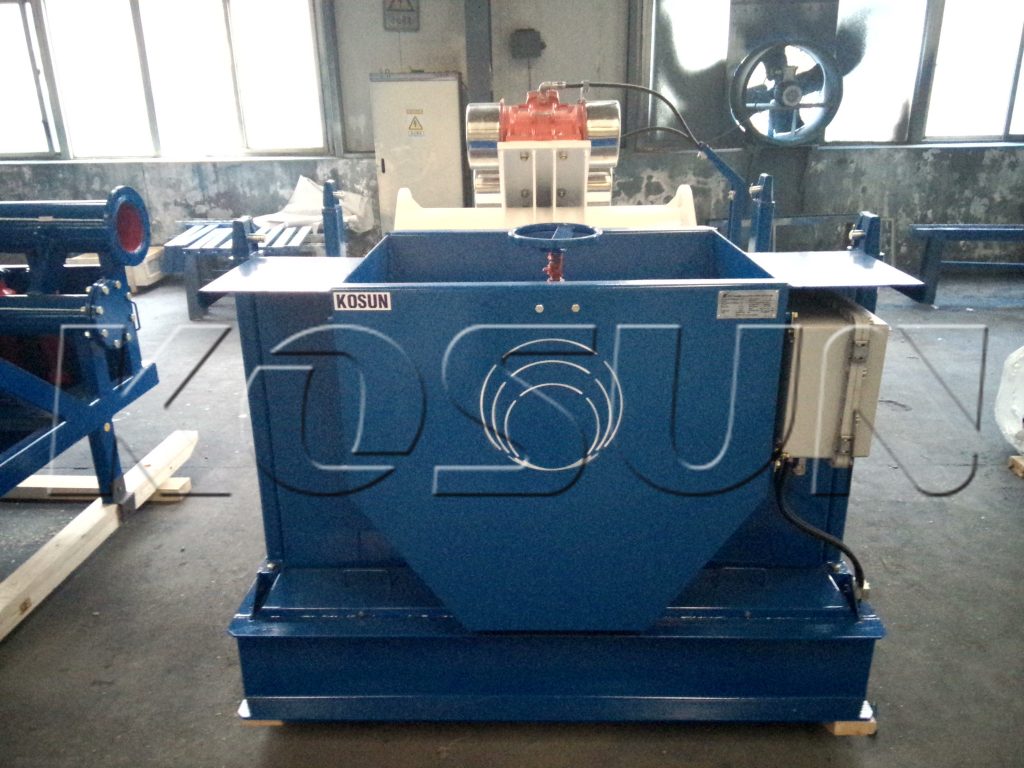

With the development of drilling technology, drilling depth is deeper and deeper, and mud requirements are more and more strict. Some complex geological conditions under the ordinary mud shaker can no longer meet the requirements of use. Moreover, the performance of the ordinary drilling vibrating screen is not very stable, and the effect of drilling vibrating screen treatment can not be adapted according to the drilling geology, often there will be some run-slurry or “horseshoe effect”. The appearance of the translational elliptical vibrating screen has solved these problems.

The translational elliptical vibrating screen USES 2 vibration motors of different sizes and keeps them on a datum level. Due to the different steering and excitation force of the two motors, the motion trajectory is elliptical. And the movement track of the whole sieve box of the translational elliptical vibrating screen is the same. The ellipse of the translational ellipse vibrating screen is different from the ordinary ellipse, the ellipse track and the screen have a certain Angle, so the “horseshoe effect” is avoided.

Advantages of translational elliptical vibrating screen:

The liquid-gas separator is mainly used to deal with large bubbles in drilling fluid. When gas invasion occurs, throttle exhaust operation should be carried out. When overflow occurs, kill the well; Drilling fluid enters the liquid-gas separator from the throttling manifold for degassing.

The drilling fluid separated from the above two conditions has small bubbles, which enter the vibrating screen for degassing, flow to the sunk sand bin, and then enter the vacuum degasser device for conventional degassing.

In the ultra-high pressure gas well drilling, because into the cylinder gas volume, liquid volume is very different. This requires that the treatment capacity of the separator should have a relatively wide range of adaptability, and its treatment capacity of gas and liquid should be able to meet the needs of well killing construction. In the design of the scheme, the following considerations should be taken into account: