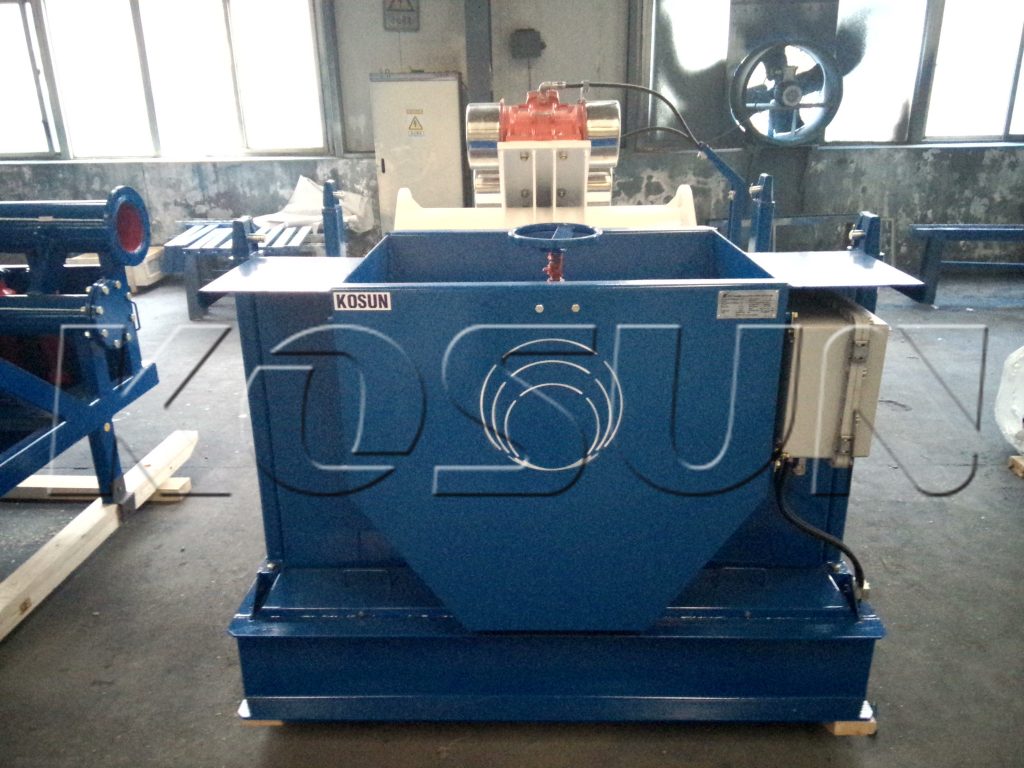

Which is a good Drilling mud Decanter centrifuge manufacturer? The first choice is KOSUN. KSOUN is an environmental protection company integrating research, development, production and sales. KOSUN produces three kinds of Drilling mud Decanter centrifuge, including DC series horizontal screw sedimentation centrifuge, hydraulic centrifuge and three-phase centrifuge. Drilling Mud Decanter Centrifuge is a machine that uses centrifugal force to separate liquid and solid particles or liquid and liquid mixtures. Because of the high speed rotation of the drum, the liquid and solid phase of drilling fluid have great centrifugal force. The centrifugal force difference between the liquid and solid phases is the centrifugal settling force acting on the particles, which causes the solid-liquid separation.

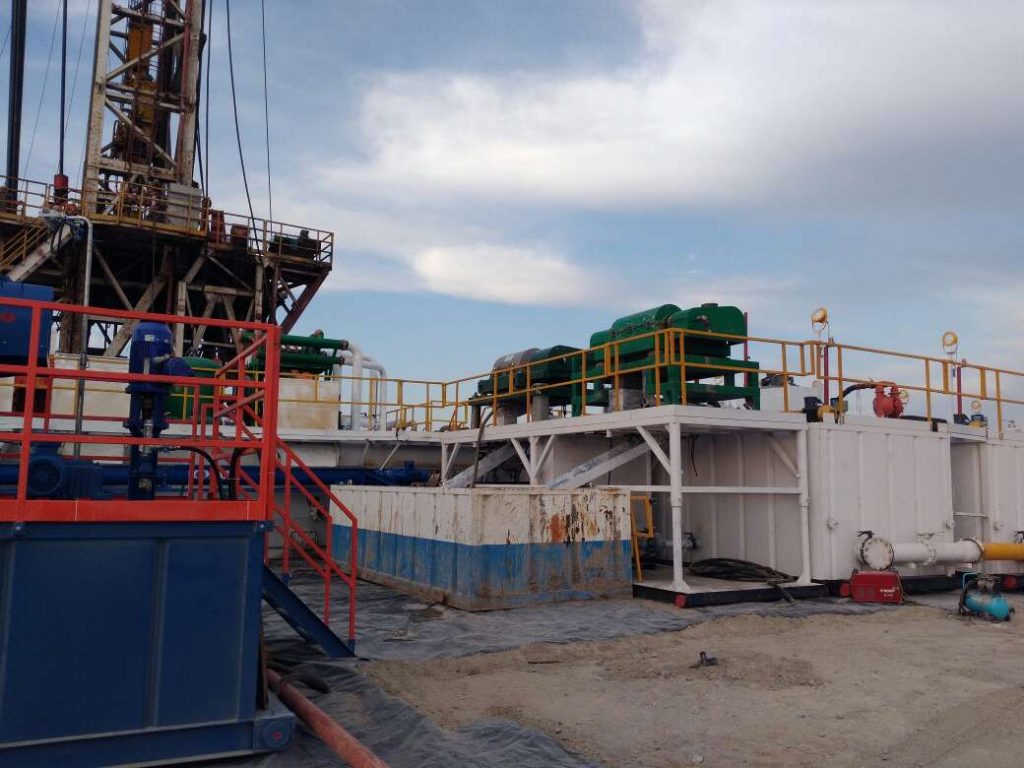

KOSUN Drilling Mud Decanter Centrifuge is mainly used to balance the viscosity and specific gravity of drilling fluid and recover the heavy gold and stone powder in the drilling fluid. It mainly separates 2-5 m and 5-7 m solid particles in drilling fluid, which is one of the important equipment in oil drilling, coal bed methane drilling and environmental protection waste mud treatment field.

Features of KOSUN Drilling Mud Decanter Centrifuge:

The solid-phase impurities in the liquid were separated by the Drilling Mud Decanter Centrifuge to achieve the clarification effect. Used for separating various difficult to separate suspensions. It is especially suitable for solid-liquid separation with small concentration and high viscosity, fine solid particles and small weight of solid and liquid. KOSUN Drilling Mud Decanter Centrifuge can meet with different requirements of mud treatment under various drilling conditions, that can do sedimentation and separation for particles more than 2 μm. After treatment, the mud can achieve ideal viscosity and proportion, resulting in better recycling, high efficiency, saving and environment protection.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com