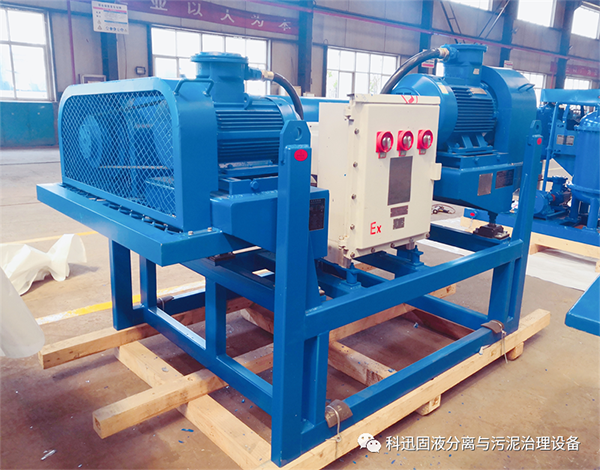

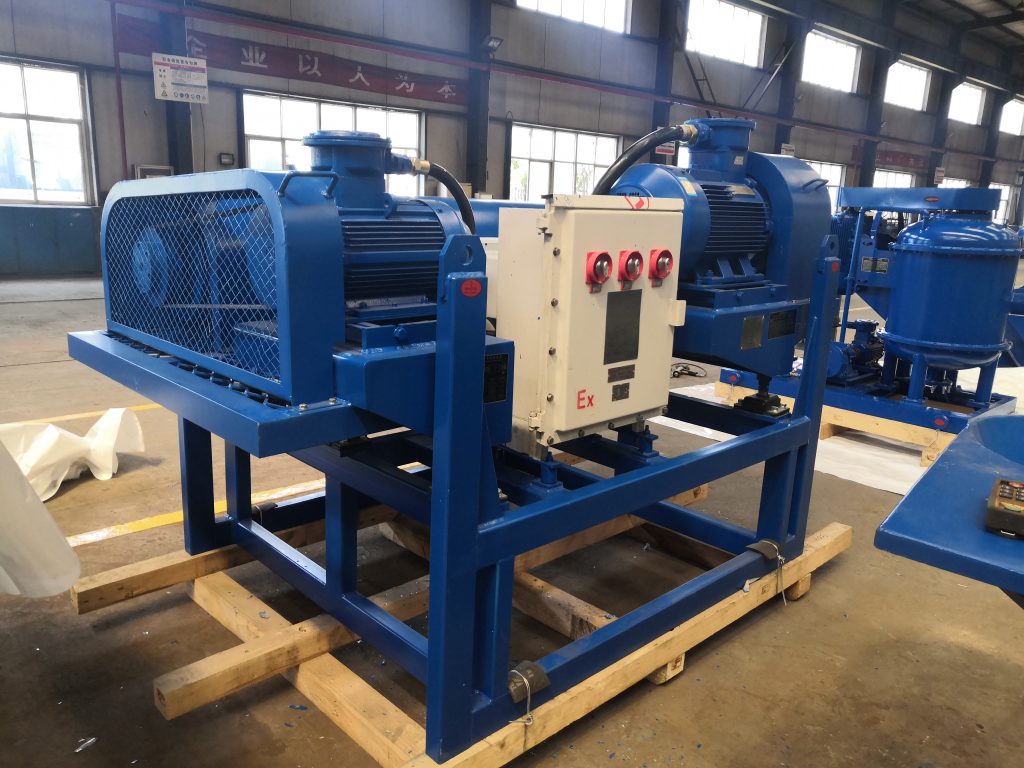

Does your oilfield operation need a high-speed decanter centrifuge? KOSUN decanter centrifuge is your best choice! This cutting-edge equipment is designed for efficient separation and clarification of various liquids in the oil and gas industry. With a wide range of applications, KOSUN decanter centrifuges are a versatile and reliable solution.

One of the main applications of KOSUN decanter centrifuges is the treatment of dewatered sewage, sludge, and suspensions. It effectively removes moisture and separates solid particles from liquids, resulting in cleaner, more manageable waste. This is critical to maintaining environmental regulations and ensuring the smooth operation of oil fields.

In addition, the KOSUN decanter centrifuge can also be used to concentrate sewage or sludge. By extracting the liquid components from these mixtures, they can be processed more efficiently and reduce overall waste volume. This not only saves time and money but also minimizes the environmental impact of operations.

Another distinctive feature of the KOSUN high-speed decanter centrifuge is its ability to clarify different types of liquids. Whether you need to separate two immiscible liquid or solid phases, this device can handle it. Its large drum and high-speed operation enable efficient separation based on particle size and density.

When it comes to product functionality, KOSUN Machinery prides itself on providing customers with free technical consultation. Additionally, their decanter centrifuges come with installation and commissioning services to ensure a smooth installation process. This level of support sets them apart from their competitors and ensures your operations run seamlessly.

In addition, KOSUN high-speed decanter centrifuges are specially designed for drilling mud processing and drilling waste processing. Complies with all industry standards and has US API and EU CE certification. This ensures its quality and reliability in the harsh oilfield environment.

In order to improve user experience, KOSUN high-speed decanter centrifuge can also be equipped with PCL touchscreen electrical control cabinet for intelligent monitoring. This advanced feature allows easy operation and real-time monitoring of equipment performance.

In summary, KOSUN high-speed decanter centrifuges are the perfect solution for all your oilfield separation and clarification needs. Its diverse applications, advanced features and reliable performance make it a valuable asset to any operation. Contact KOSUN today for a free technical consultation and learn how their decanter centrifuges can optimize your oilfield processes.