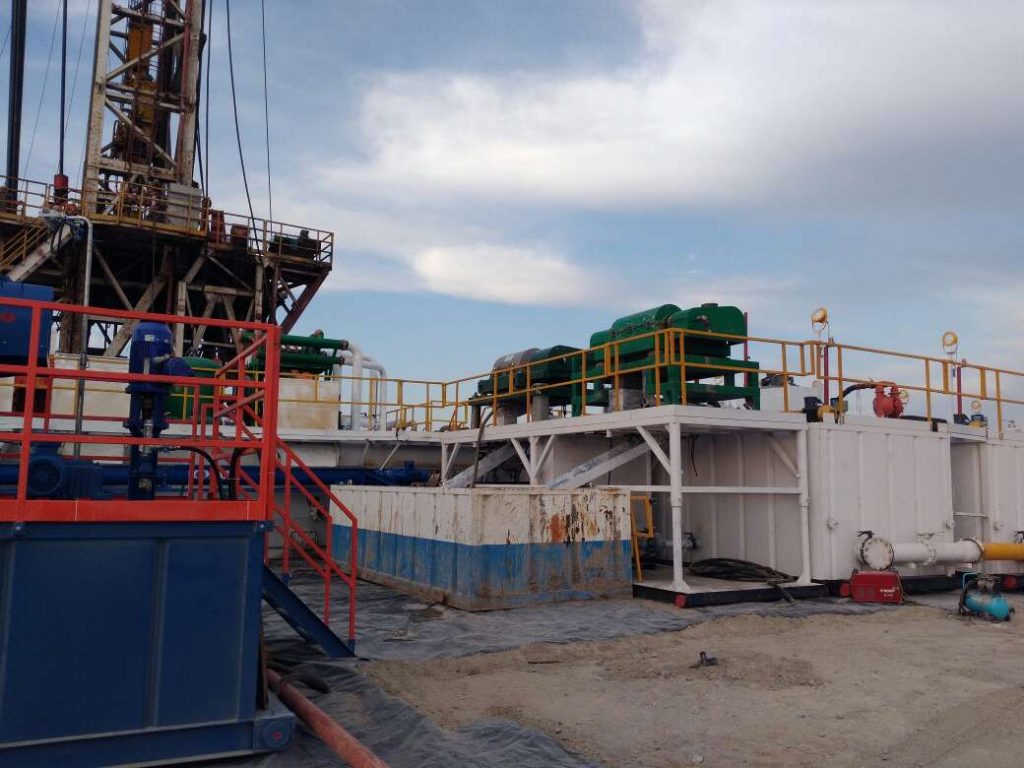

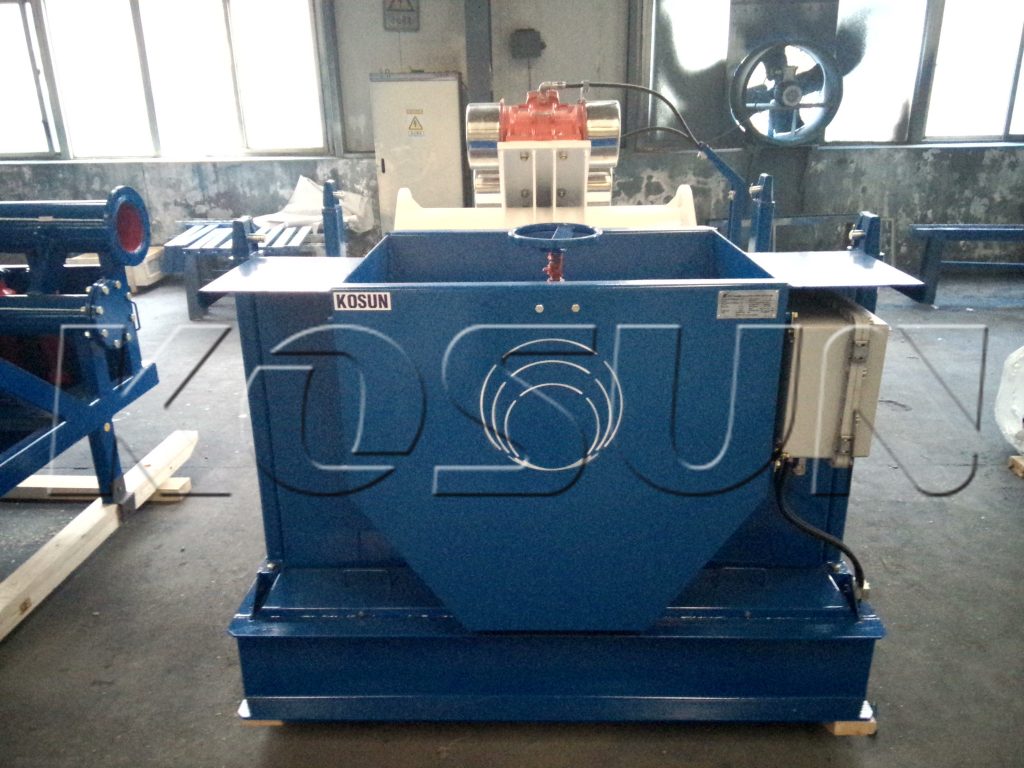

What is the solid control system drilling waste treatment equipment? Among them, drilling waste treatment equipment mainly includes vertical drilling cuttings dryer, drying screen, screw conveyor, solid waste treatment equipment, etc. KOSUN can provide customers with oil and gas drilling solids control equipment, centrifuge series products, drilling waste treatment equipment, etc.

Solid control system drilling waste treatment equipment function: through the principle of centrifugal separation, the solid and liquid phases are separated. The cuttings dryer can effectively recover the liquid phase in the drilling cuttings and make the solid phase very dry. It is suitable for water-based mud, oil-based mud and synthetic-based mud. Drilling costs, but also reduce environmental pollution. It can be flexibly assembled and used in different drilling sites, with simple operation, stable structure, strong adaptability to working space and high safety performance, thus greatly improving the working efficiency of the equipment and saving costs and resources. The screw blades of the screw conveyor are made of wear-resistant materials to ensure their service life.

Features of solid control system drilling waste treatment equipment: Efficient solid-liquid separation can minimize the mud content in drilling cuttings and reduce the amount of waste treatment. Advanced and reasonable design, combined with advanced manufacturing technology and perfect quality assurance system, make it have significant advantages such as small size, large bearing torque, low noise, and no oil leakage. The scraper of the inner rotating body is sprayed with tungsten carbide anti-corrosion and wear-resistant material, which can prolong its service life and reduce maintenance costs.

KOSUN- China Solids Control Leader&Drilling Waste Management Expert

Email: sales2@adkosun.com

WhatsApp/Wechat:+86 18792396268

Contact person: Lily Wang

Online consulting:

http://www.kosun.com

http://www.kosuneco.com